Micro Balancer

Dynamic balancing of the spindle system while the wheel is attached to the machine.

Feature

・ Easy-to-understand dialogue. You can easily and accurately perform balancing by following

the instructions on the screen.

・ Because balancing is carried out with the brush attached to the machine in a rotated state,

dynamic balance adjustment including unbalance of the machine and the shaft system sensed

by the vibration sensor is performed.

Vertical Rotary Dresser

CBN ・ Diamond wheels easily truing ・ dressing

Feature

・ In addition to the structure that supports the whetstone with the vertical shaft,

the special design of the motor built-in realized 3 times the rigidity of the conventional

product.

・ Truing can be done about 5 times faster than conventional products.

・ In the horizontal axis type, the dressing / truing condition changes due to the speed

change due to the outer diameter decrease of the dressing toilet, but the condition

does not change in the vertical shaft type.

※ To use this equipment, "Toy axle continuously variable transmission" is a required option.

Rotary Chuck

The epoch making tool appeared after the sign bar chuck

Feature

・ Innovative function expansion tool born from the mold manufacturing site.

Rotating machining which is impossible in the past can be easily realized with high precision.

・ Semi-convex, medium concave machining is also possible by using the bar bar chuck.

The forming grinding machine / surface grinding machine will be able to move in the same way as a small rotary grinding machine in 5 minutes.

Twin-Bix

Incredible grinding efficiency. Reduce cycle time from general grinding.

Feature

・ Prevent clogging of the grinding wheel due to cavitation.

・ Coanda effect improves coolant penetration.

・TWINBIX's cooling effect is 30% higher than conventional BIX.

・Coolant permeates the grinding wheel to suppress heat generation.

Quick Touch

Achieving high precision measurement easily and quickly on a grinder

List of target series

- CNC High Precision Molding Grinder HPG-NC Series

- Precision surface grinder PSG-SA1 Series

Feature

・ This is a unit option that allows easy and speedy on-board measurement with

a surface grinder.

・ No program required, measurement can be made just by touching the work measuring unit.

・It greatly contributes to the reduction of the remeasurement time of work and the operator's setup time.

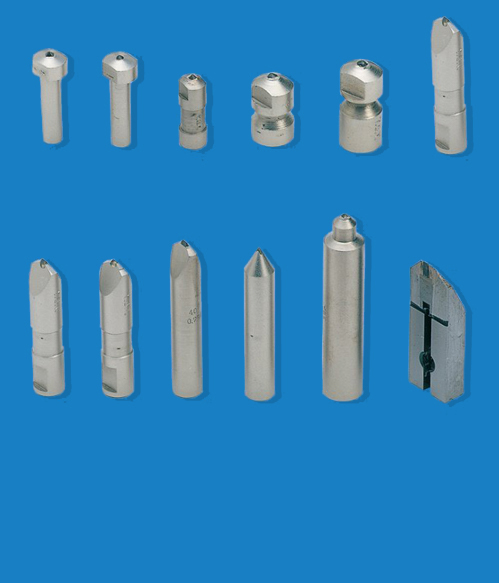

Dia Tools

Grinding quality changes with truing / dressing

Feature

・ Innovative function expansion tool born from the mold manufacturing site.

Rotating machining which is impossible in the past can be easily realized with high precision.

・ Semi-convex, medium concave machining is also possible by using the bar bar chuck.

The forming grinding machine / surface grinding machine will be able to move in the same way as a small rotary grinding machine in 5 minutes.

・Dressing (dressing) to crush the abrasive grains on the clogged face of the sprout to make

a cutting edge.

・Truing (reforming) make the shape of the palm concentric with the outer diameter of

the brush and the center of the shaft.

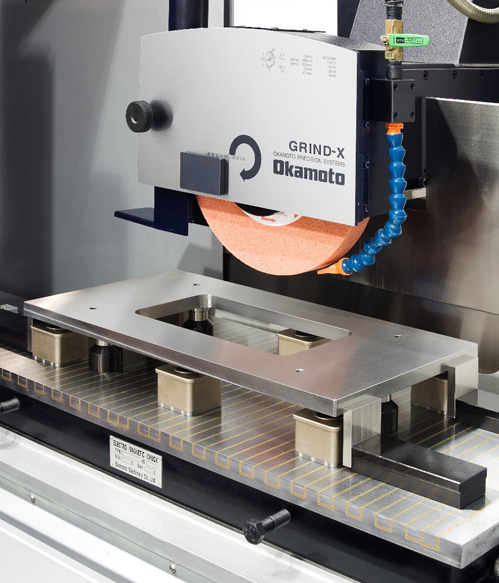

SG Master

Do not you have trouble with "warpage"

Feature

・ Easy setup

Instead of spacers, shims, bean jacks etc. used in conventional warpage work, it is possible

to apply the magnetic force of the magnet chuck and hold the invisible surface of the material

as it is.

・ Suitable for all kinds of materials

Magnetic force is used only for holding jigs and is not transmitted to the material, so it is ideal for not only magnetic material but also non-magnetic aluminum, stainless steel, resin etc.

・ Excellent planar accuracy

Grinding while retaining the incorrect surface of the material as it is, and also grinding while absorbing the strain during grinding ensures micron precision with a single grinding even

for materials with large warp and twist.