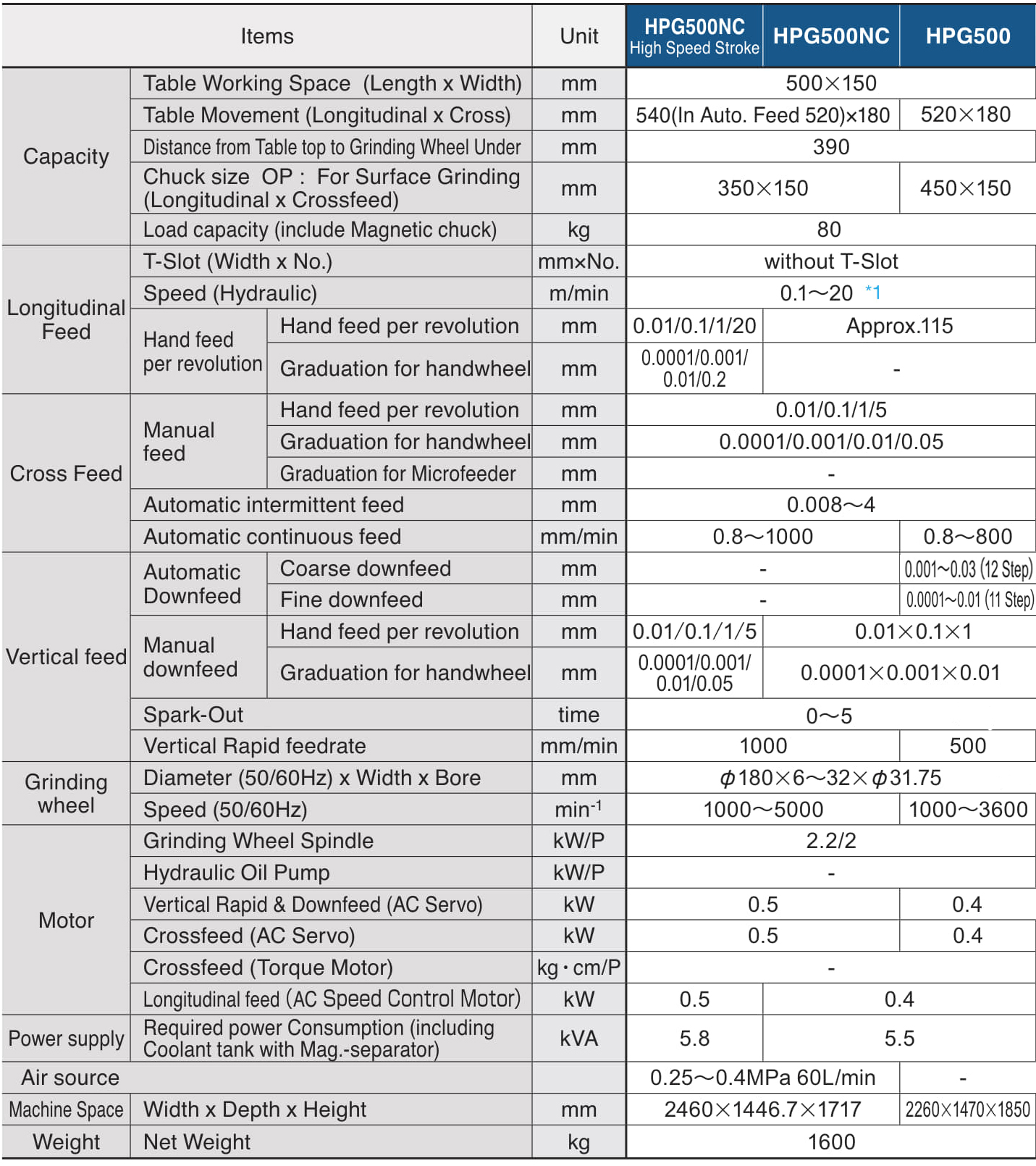

ACC350II

Simply the best machine for precise form grinding developed from our long experience in Grinding Machine Field

Features :

- Spindle & motor 1.5 Kw. low vibration concealed type spindle motor. Angular contact ball bearing at front / rear side of spindle.

- Lubrication automatic lubrication system for all slide-ways. Table movement - Turcite material is used on table slide way & timing belt is employed to have smooth & slip free movement.

- Rigid Design and High Precision casting construction with small footprint.

- Fast setup operator can start job immediately.

- Longer stroke in Cross Feed for various kind of attachment add on.

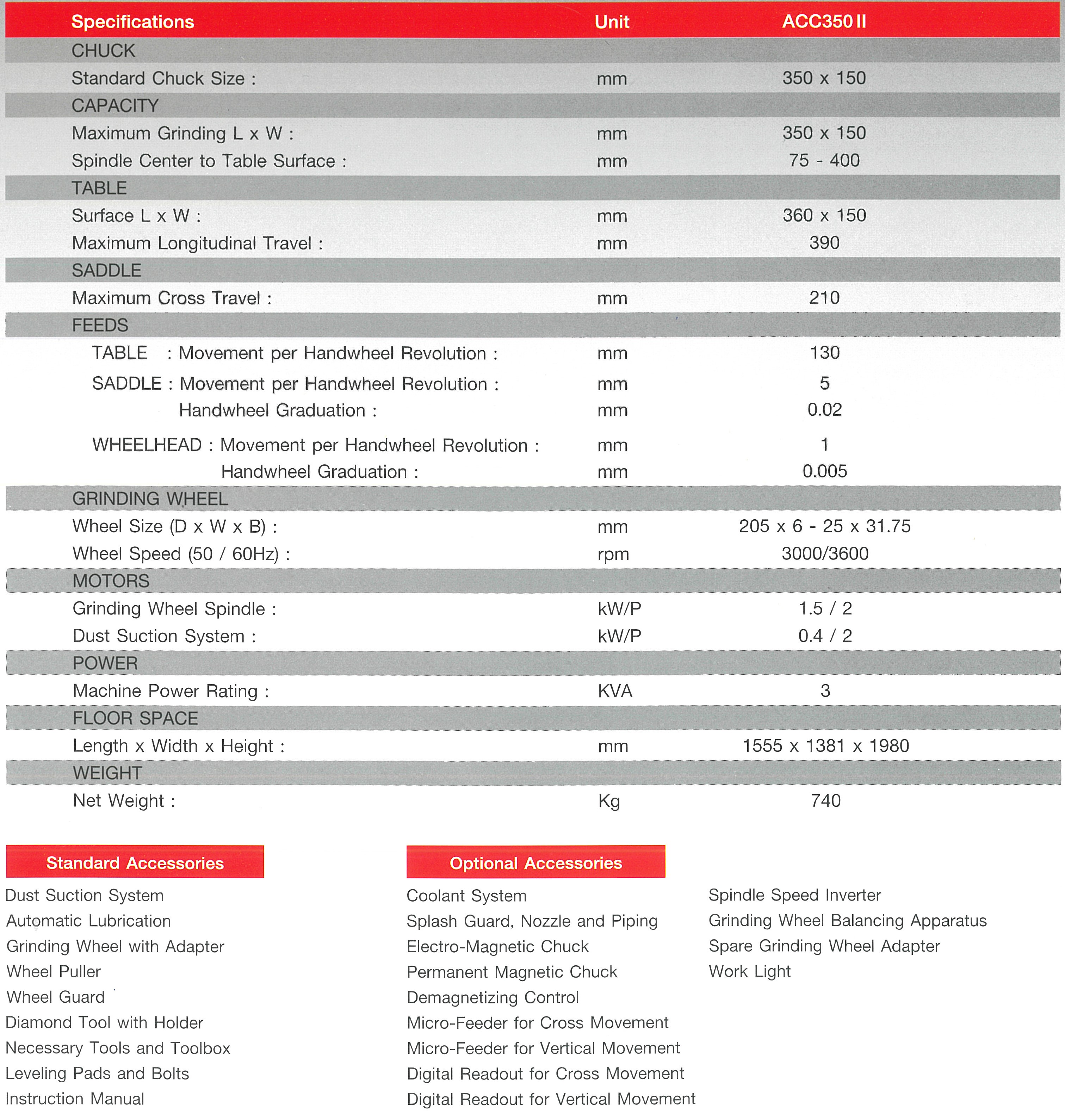

Linear B Series

Superior design and construction combined with enhance features make the LINEAR B Series the ultimate in precision hand-feed form grinders.

Features :

- Smooth Table Movement though reliable belt drive. Beefy, Heavily Ribbed Meehanite cast construction provides superior rigidity and optimum grinding accuracy.

- Designed for Long-Team Trouble-Free Performance.

- Recirculation automatic lubrication system assures adequate lubrication to critical components.

- No-maintenance "lubed-for-life" cartridge type grinding wheel spindle standard.

- Conveniently located, extra-large handwheels optimize operator control, convenience and comfort. Available in to popular sizes 350 x 150 mm and 450 x 150 mm.

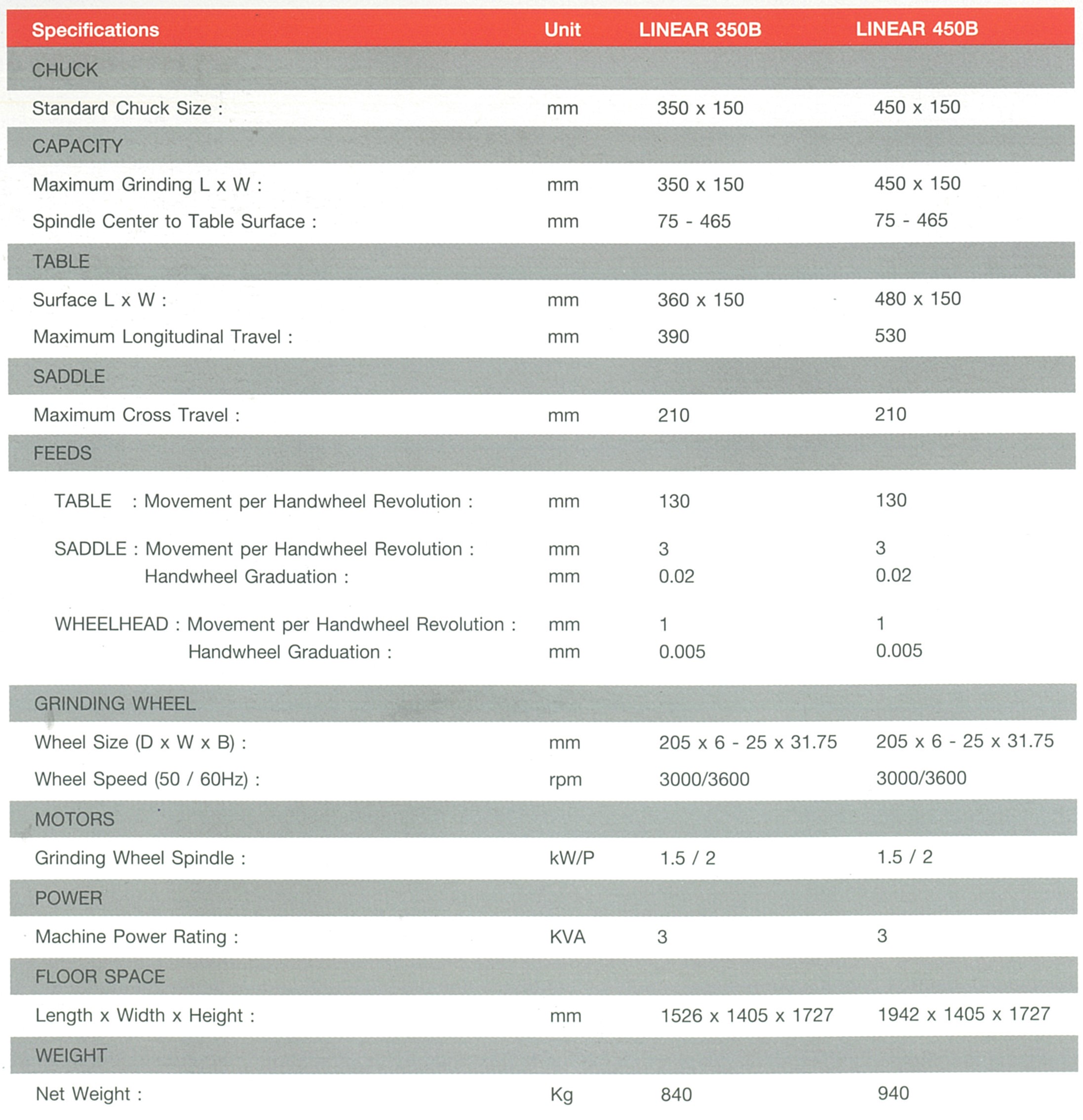

ACC450V Series

Machine Lineup

- ACC 450AV

- ACC 450BV

- ACC 450CV

- ACC 450PV

Simply the best machine for precise form grinding developed from our long experience in Grinding Machine Field.

Features :

- Table surface parallelism with 6 pieces grinding under 0.005 mm.

- 1.5 Kw. low vibration concealed type spindle motor. Angular contact ball bearing at front / rear side of spindle.

- Vertical movement by AC servo motor c/w minimum down-feed of 0.0001 mm.

- Cross movement slide-ways c/w double V-V and table longitudinal slide-ways c/w double V-V with TURCITE coated and precision hand scraped.

- Longitudinal table driven by hydraulic with feed range from 1m/min to 20m/min. Easy operation and vibration-free reversing motion by proximity sensor switch.

- Automatic lubrication system for all slide-ways separated from main hydraulic system.

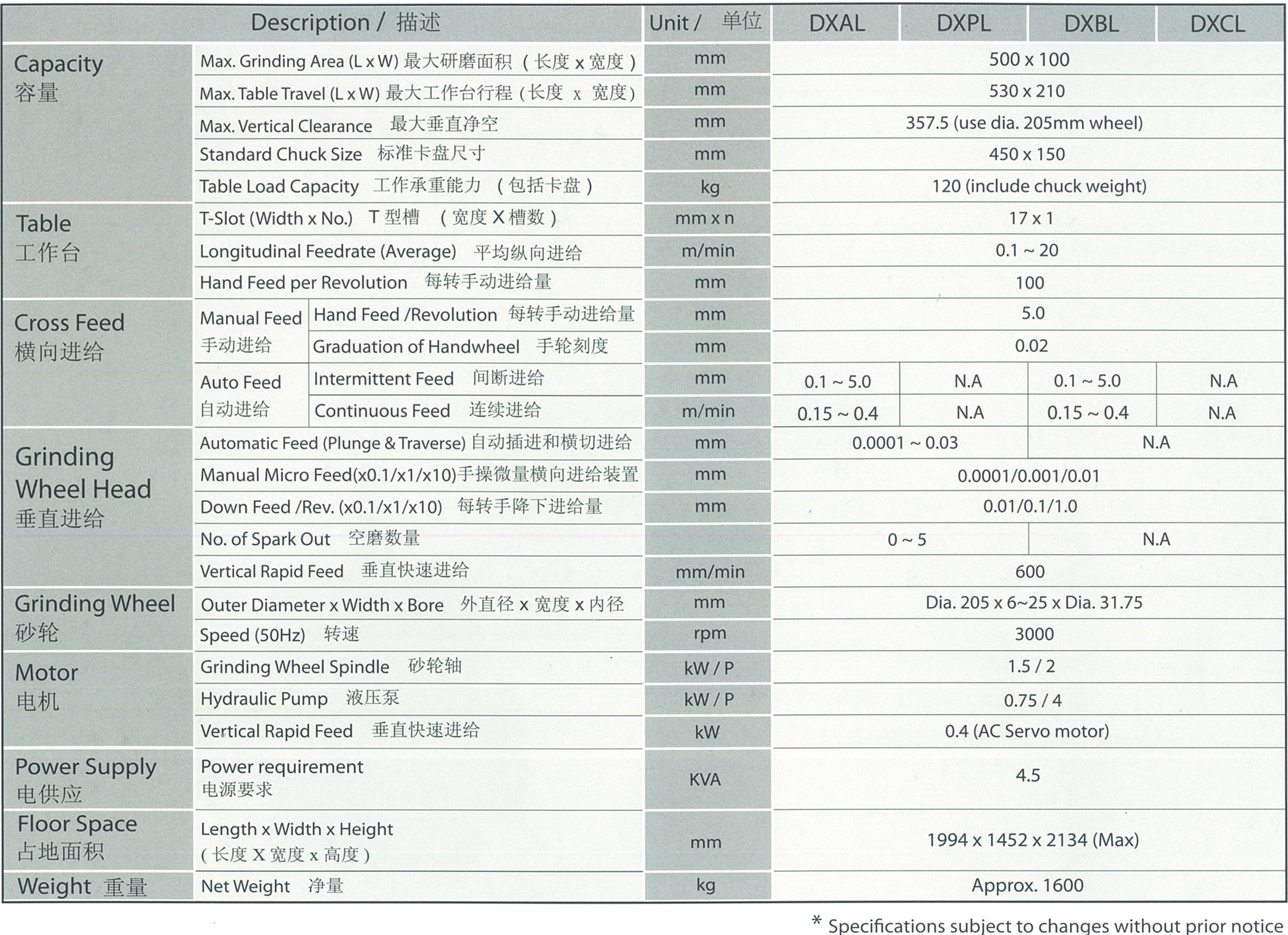

ACC515DX Series

Machine Lineup

- ACC 515DXAL - Fully Auto

- ACC 515DXBL - Longitudinal & Cross Axis Auto

- ACC 515DXCL - Longitudinal Auto

- ACC 515DXPL - Longitudinal & Vertical Axis Auto

● All main castings are taken to shape in the extra rigid type through computerized structure analysis by finite element method

● Concealed type spindle motor with increase to 2HP for greater performance

Features :

- Deeper V-V slideways for greater durability, accuracy and stability.

- Thanks to the State-of-Art of AC Servo Motor, 0.0001 mm is easily selectable for Vertical Rapid Feed.

- Manual Pulse Generator for Vertical Feed.

- Release connection to Hydraulic Piston for easy table movement.

- Individual Oil Tank for Table Slideways & Lubrication.

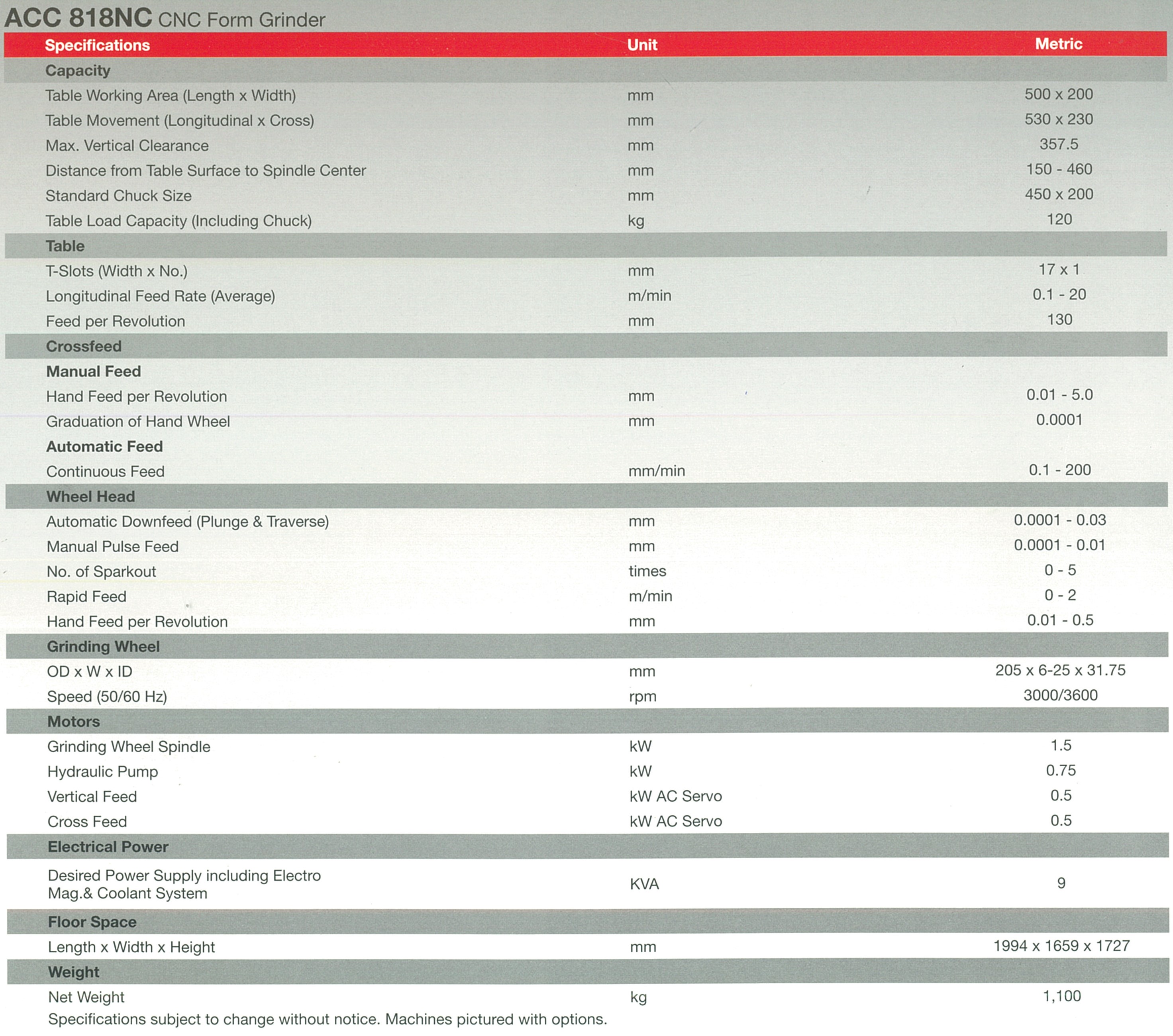

ACC818NC

The ACC 818NC Form Grinder deliver the benefits of a full-function CNC surface grinder at a fraction of the price. It's loaded with performance feature and the powerful control affords you a full array of grinding capabilities.

Features :

- Superb construction with heavily ribbed Meehanite cast construction.

- Full contact Double Vee for true tracking and unrivaled accuracy.

- 3-point diamond dresser includes one 2-point angle dresser for form dressing and one 1-point dresser for straight dressing.

- Set up to 4 different table stoke positions. ideal for multiple workpiece grinding.

- Ideal for surface, Slot, Step, Form and Contour Grinding.

- User-friendly "Touch & Teach" conversational programming simplifies set-up and operation even for operators unfamiliar with CNC

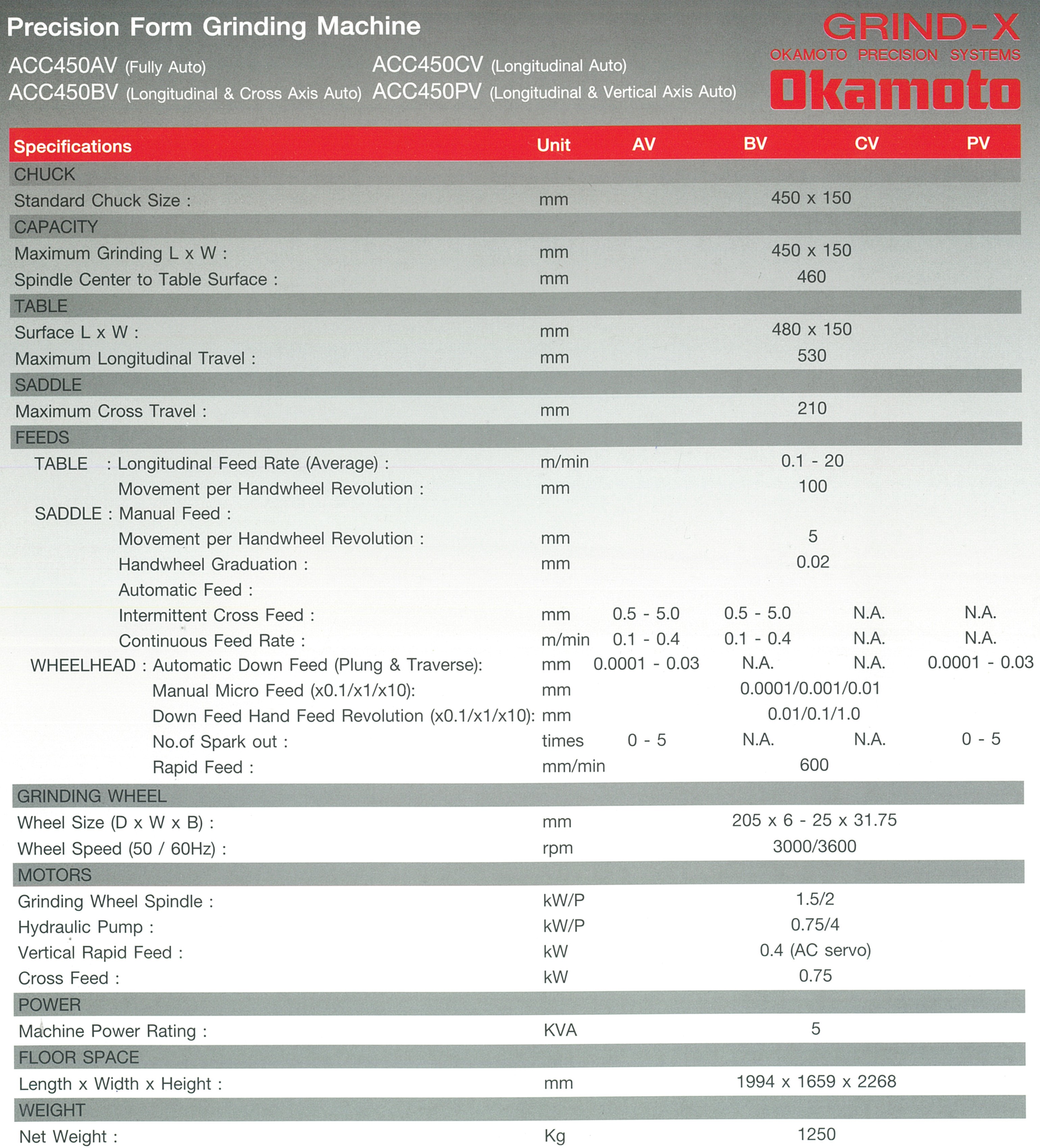

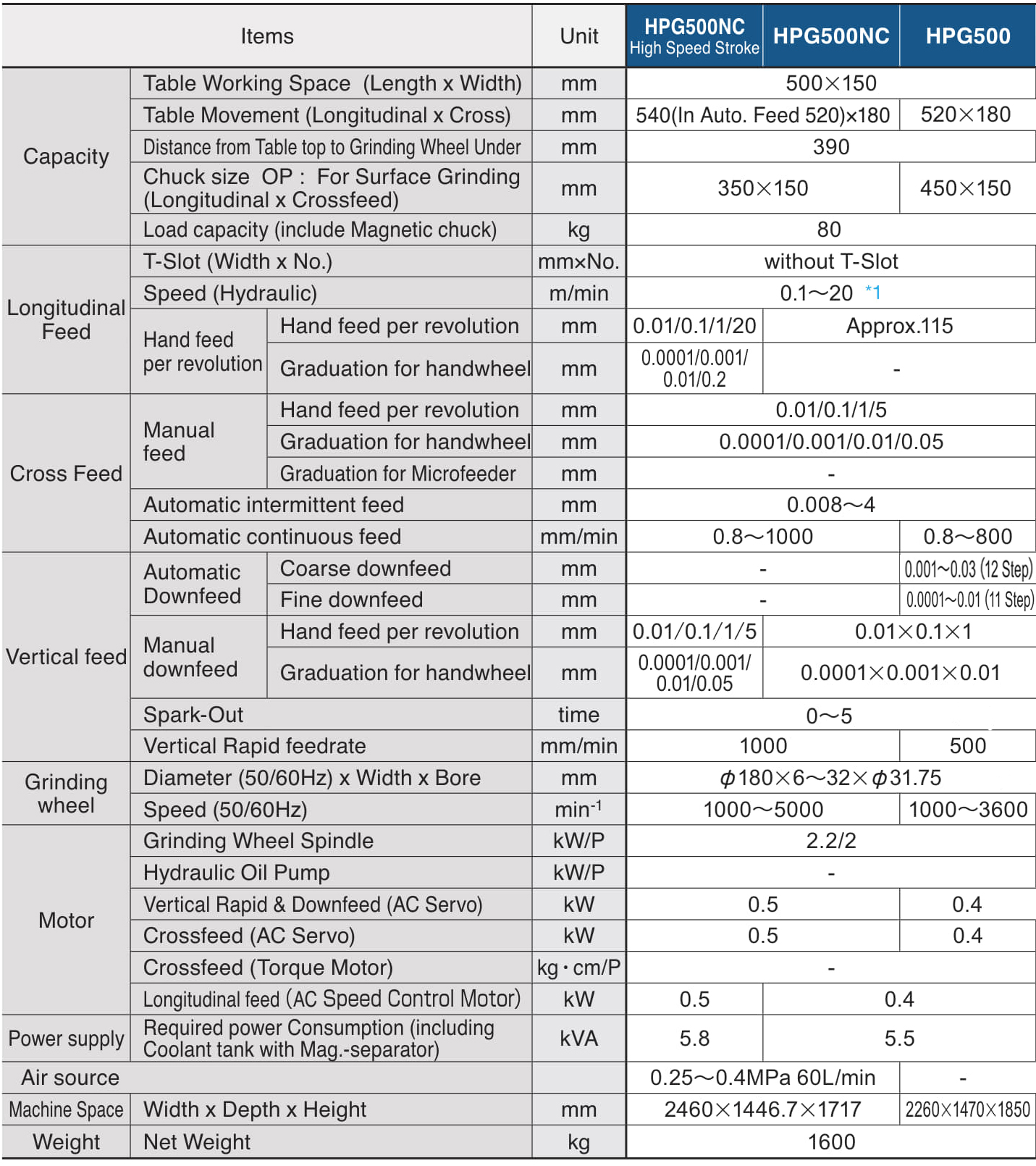

HPG500

higher Vertical and Cross positioning accuracy Form Grinder with non hydraulic oil system.

Features :

- Vertical and Crossfeed minimum setting is 0.1μm. Precision specifications by scraping alignment for longitudinal and crossfeed slide adopted V-V sliding way.

- Rigidity ratio of grinding wheel spindle is 1.45 times conventional machine. Increase the frame size for stability of the crossfeed.

- The Linear guide construction eliminates the thermal displacement, oil waste and reduces CO2 emission 199.2Kg.

- Vertical and Crossfeed scale feedback is standard specification. Wheel spindle motor 2.2kW and wheel spindle inverter also standard specification.

HPG500NC

Machine Lineup

- HPG500NC - Standard Specifications

- HPG500NCS - Option High speed table reverse

High-accuracy positioning with vertical and cross feed by scale-feedback control. An eco-friendly machine without hydraulic pressure.

Features :

- The vertical and cross feed is set to a minimum setting of 0.1 microns, and the left and right front-back slides use V-V sliding surfaces for high-precision specifications by traditional kisage rubbing.

- Standard SUS cover adopted, life of machine cover increased.

- Spindle rigidity is 1.45 times that of conventional grinders. The frame has been enlarged to improve cross feed accuracy.

- Suppresses thermal displacement without hydraulic pressure. Elimination of hydraulic oil has achieved a CO2 reduction effect of 199.2 kg.

- Equipped with wheel molding software as standard. 3-way dressing device automates forming grinding.

- Vertical scale feedback is provided as standard. The 2.2kw spindle motor and inverter are also standard specifications and high-precision specifications.

- HPG500NC high-speed table reversal specification is available as an option. Achieves high-speed grinding such as oyster mushroom grinding.