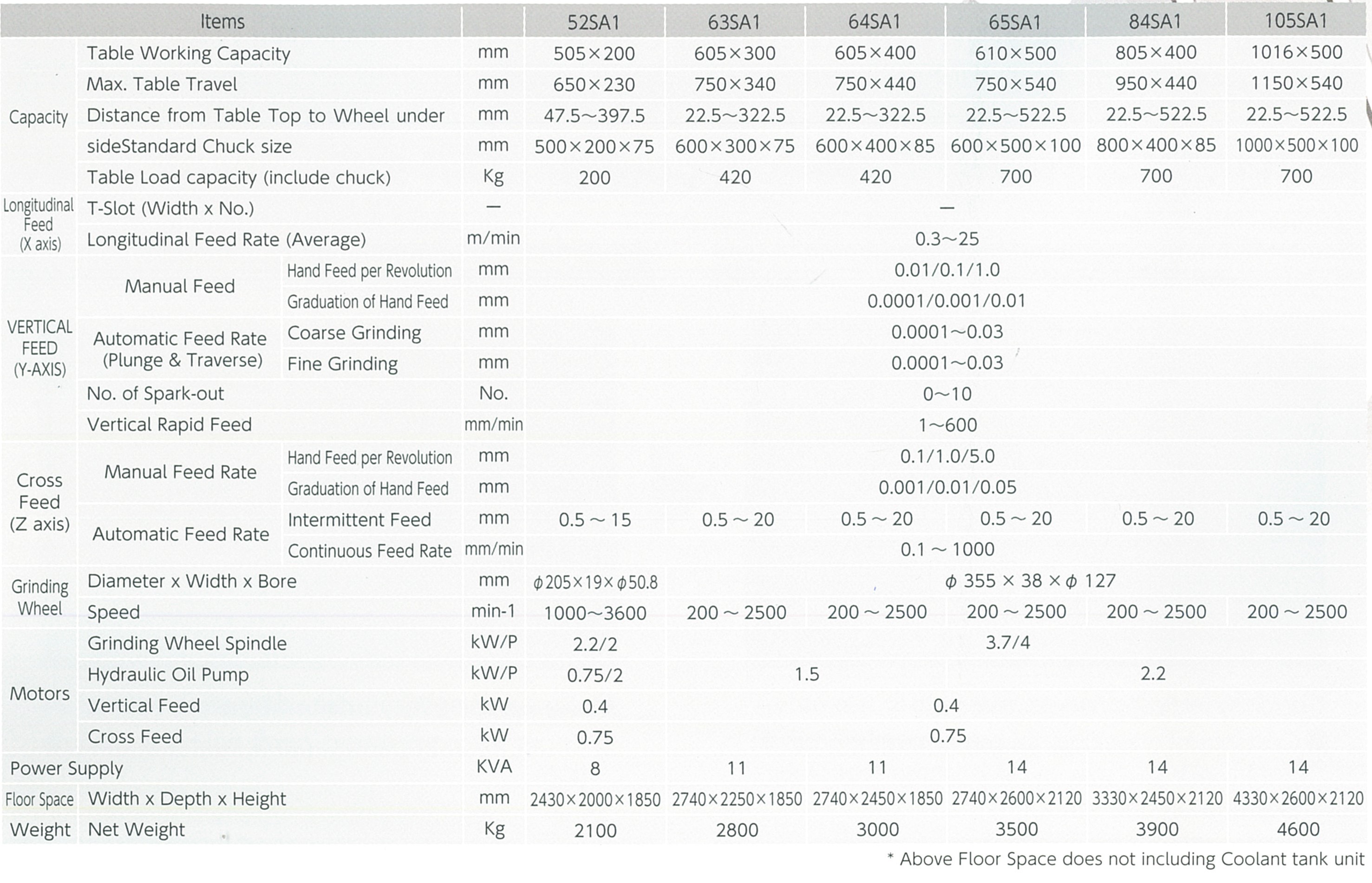

ACC-SA1

Machine Lineup Standard chuck size (LxW)

- ACC 52SA1 - 500 x 200 (mm.)

- ACC 63SA1 - 600 x 300 (mm.)

- ACC 64SA1 - 600 x 400 (mm.)

- ACC 65SA1 - 600 x 500 (mm.)

- ACC 84SA1 - 800 x 400 (mm.)

- ACC 105SA1 - 1000 x 500 (mm.)

Next Generation Standard Surface Grinder Series equipped with a newly developed user friendly controller.

Features :

- Best machine for replacement of ACC-DX Series. Ready to use machine, with easy operation.

- Position teaching system for crossfeed stroke.

- Compact footprint design.

- New control allows for easy monitoring of different information and LDC touch screen.

- Auto dress with compensation is standard.

- Spindle inverter unit is standard.

- Auto-Retract function is standard.

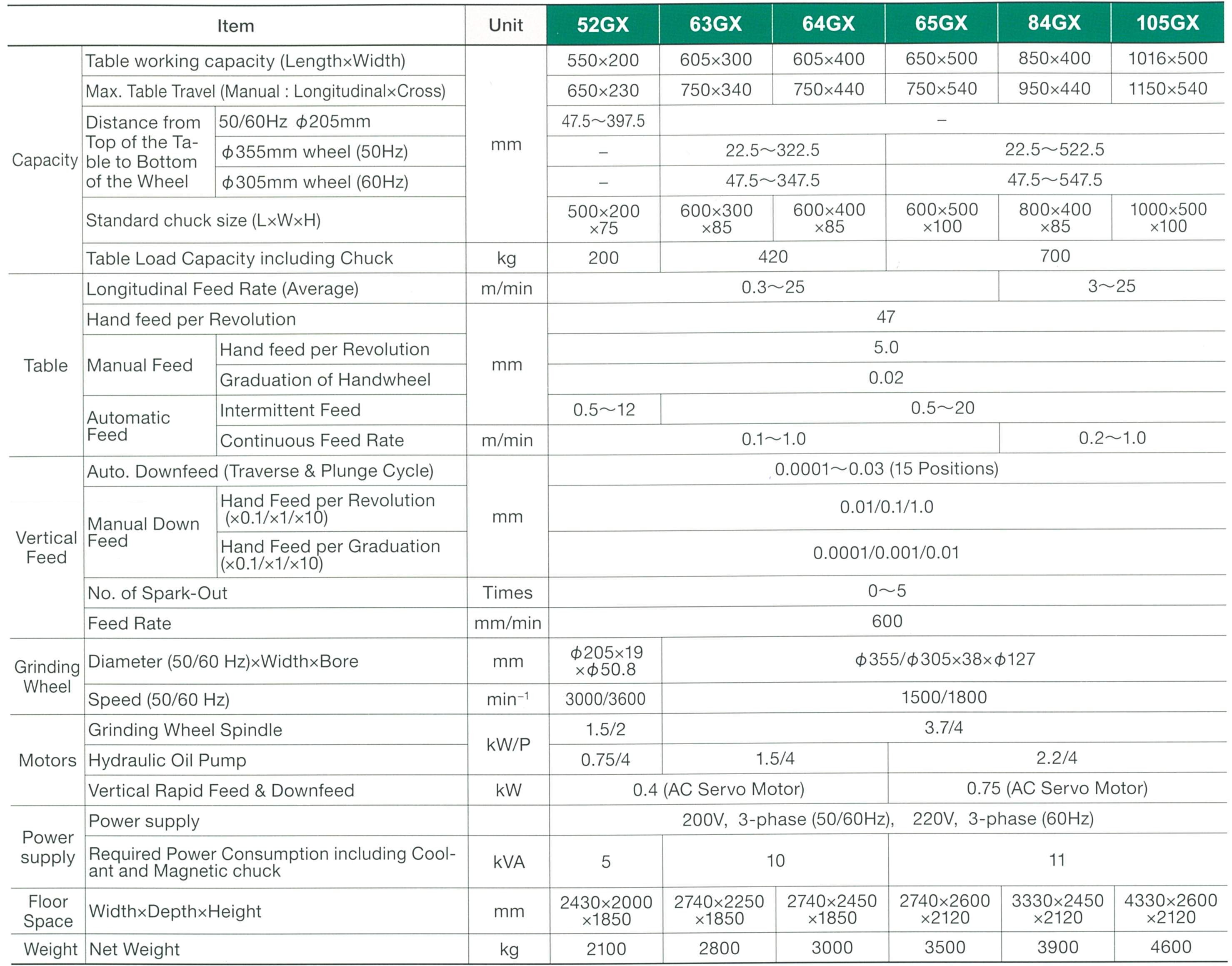

ACC-GX

Machine Lineup Standard chuck size (LxW)

- ACC 52GX - 500 x 200 (mm.)

- ACC 63GX - 600 x 300 (mm.)

- ACC 64GX - 600 x 400 (mm.)

- ACC 65GX - 600 x 500 (mm.)

- ACC 84GX - 800 x 400 (mm.)

- ACC 105GX - 1000 x 500 (mm.)

The most popular Standard Surface Grinding Machine in the world ACC-DX Series. The DX Series is succeeded by the GX Series.

Features :

- Double V Table Ways on both the Longitudinal and Crossfeed axes assures optimum performance ang long term grinding accuracy.

- Hydraulic and Lubrication Component have been re-located to out-side the machine.

- Saddle Moving type Grinder allows more space saving.

- Grinding Wheel Guard using stainless steel material.

- Allows for less operator involvement by using the hydraulic type Overhead Dresser with auto dress and compensation plus retract function.

- Achieved 0.1 µm infeed using our own developed control system.

- The control has convenient features like manual interruption, Quick set-up, precision positioning. Convenient and dependable with long term Reliabilities.

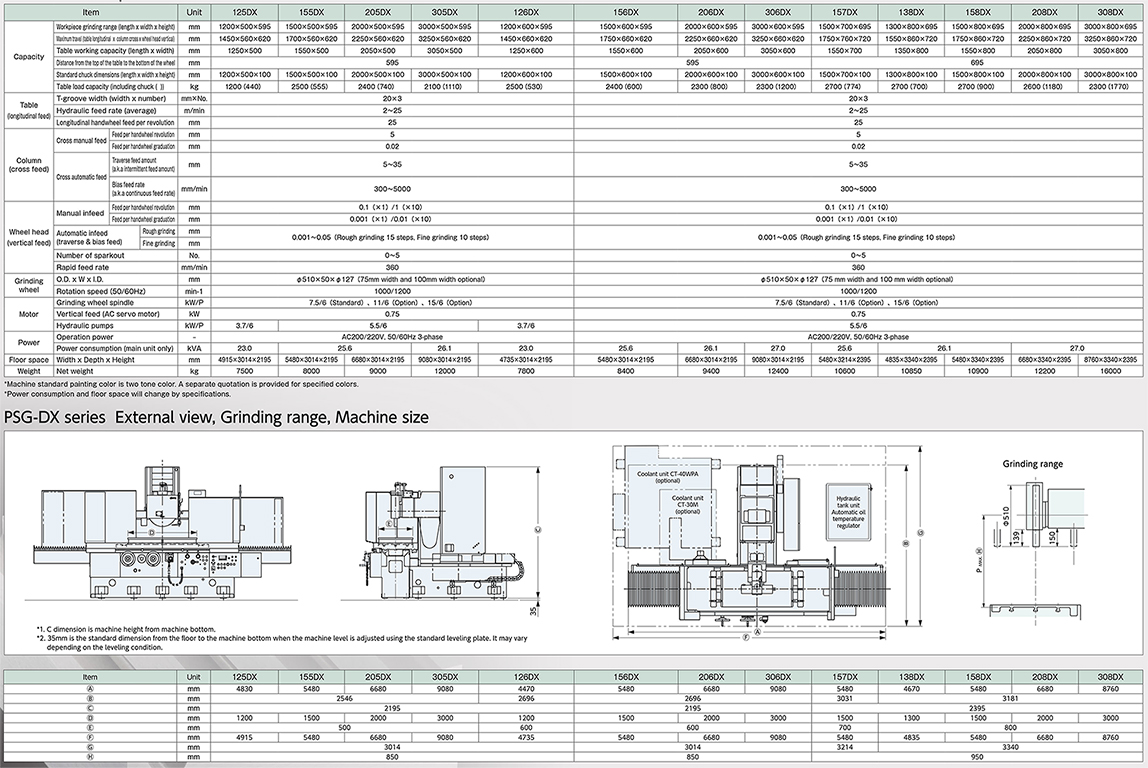

ACC-DX (Colume Traveling Type)

Machine Lineup Standard chuck size (LxW)

- ACC 125DX - 1200 x 500 (mm.)

- ACC 155DX - 1500 x 500 (mm.)

- ACC 205DX - 2000 x 500 (mm.)

- ACC 305DX - 3000 x 500 (mm.)

- ACC 126DX - 1200 x 600 (mm.)

- ACC 156DX - 1500 x 600 (mm.)

- ACC 206DX - 2000 x 600 (mm.)

- ACC 306DX - 3000 x 600 (mm.)

- ACC 157DX - 1500 x 700 (mm.)

- ACC 138DX - 1300 x 800 (mm.)

- ACC 158DX - 1500 x 800 (mm.)

- ACC 208DX - 2000 x 800 (mm.)

- ACC 308DX - 3000 x 800 (mm.)

Optimum to manual grinding of large casting and die/mold plates. Manual operation type large grinding machine integrated with original software. Vertical feed mechanism is AC servo motor feed which enables the minimum increment of 1 µm. Best selling series for flexibly grinding small to large size.

Features :

- Operator-oriented design that takes advantage of the column type

- Lubrication to guideways are by the free-fall automatic lubrication system.

- Hydraulic tank unit equipped with automatic oil temperature regulator suitable for the series is provided as a standard accessory. It supplies temperature controlled lubrication oil to all slideways.

- Wheel dimension drawing for 100 width (OP)

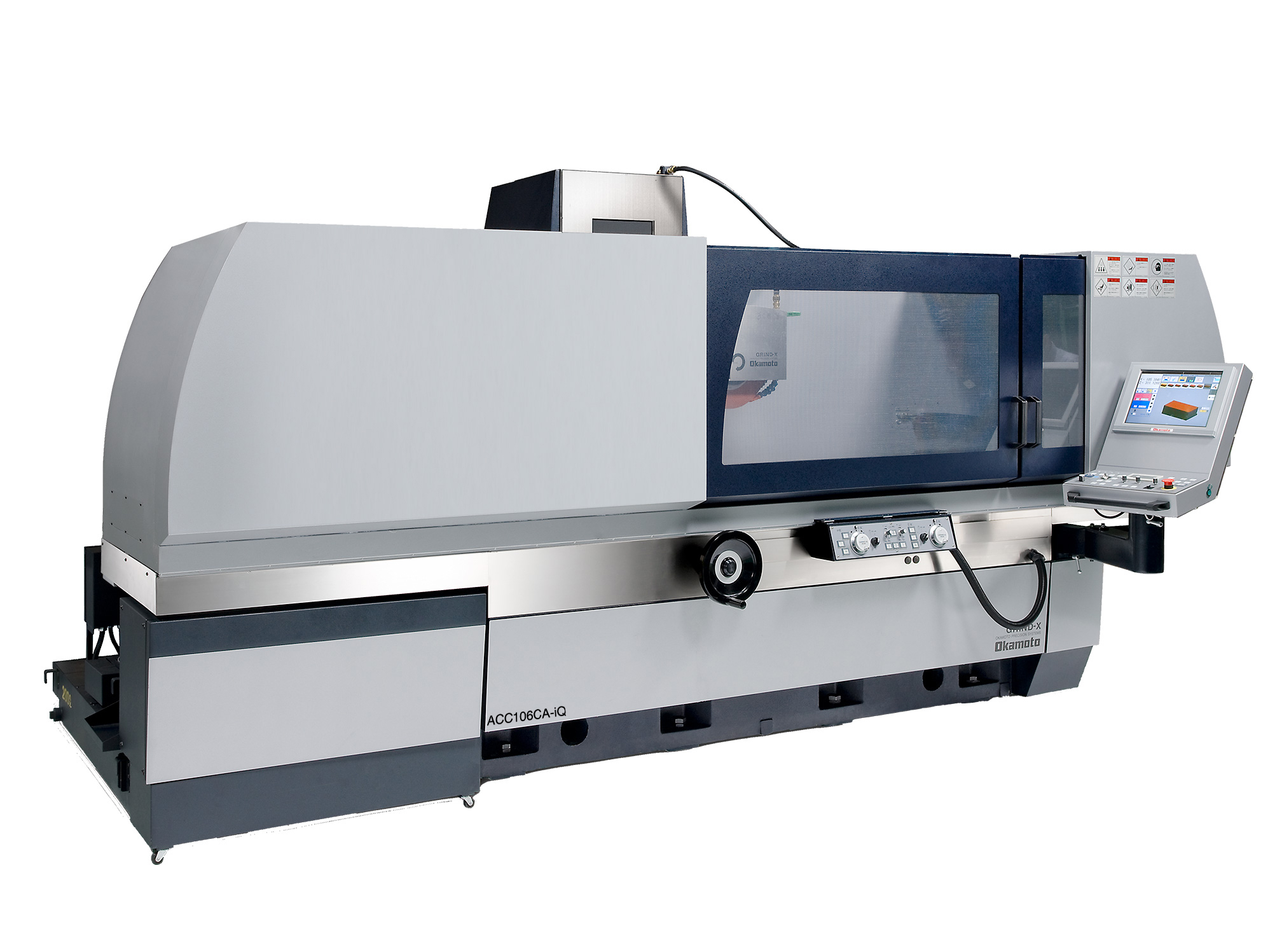

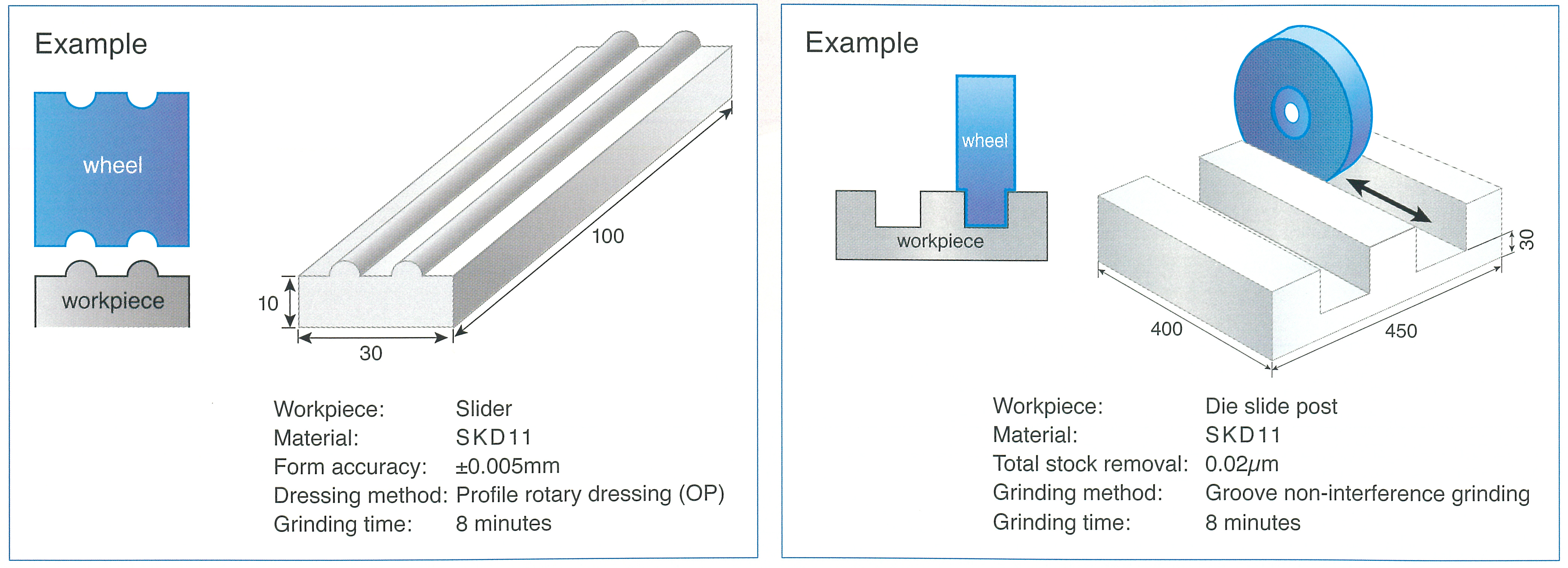

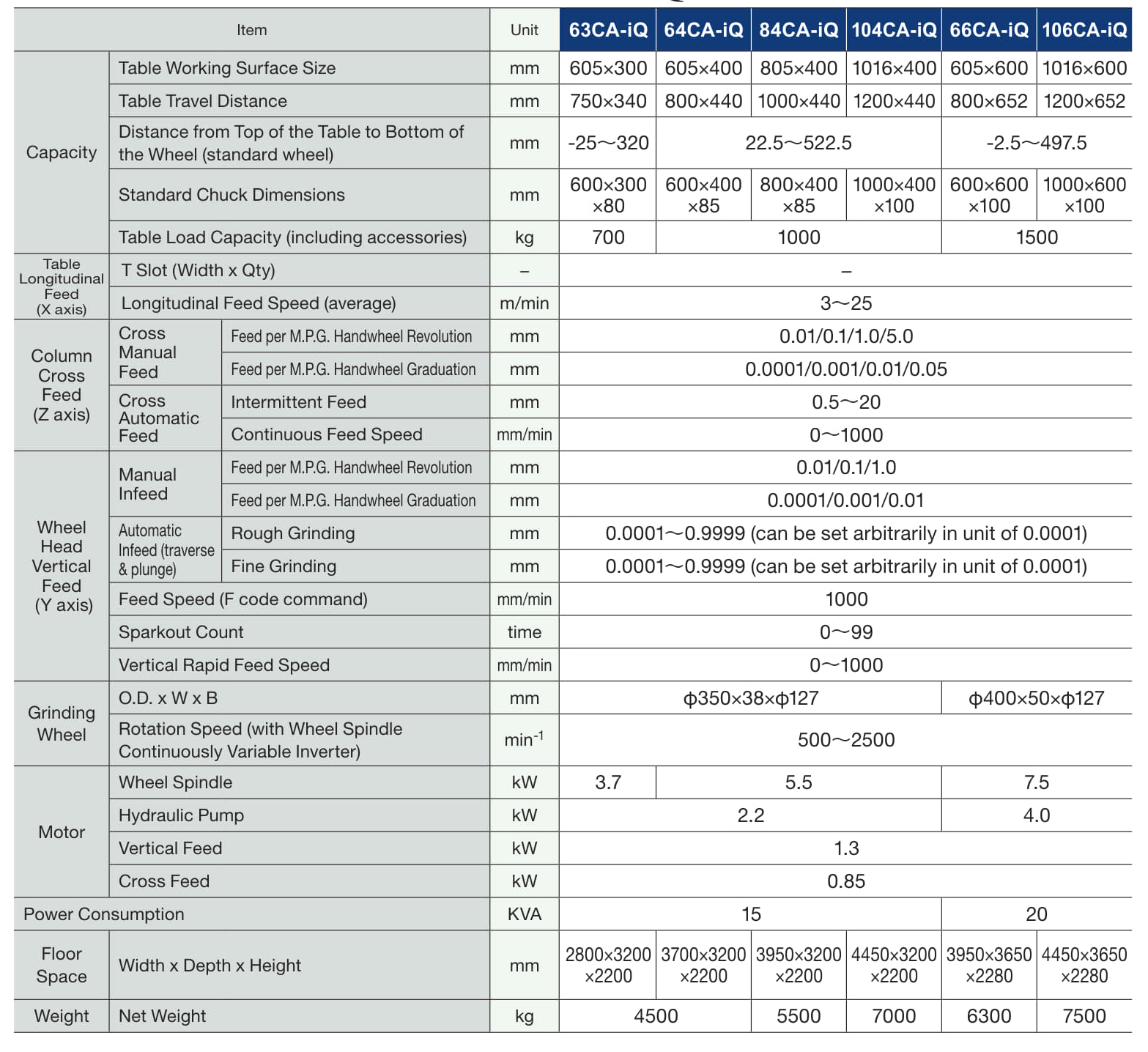

ACC-CA-iQ

Machine Lineup Standard chuck size (LxW)

- ACC 63CA-iQ - 600 x 300 (mm.)

- ACC 64CA-iQ - 600 x 400 (mm.)

- ACC 84CA-iQ - 800 x 400 (mm.)

- ACC 104CA-iQ - 1000 x 400 (mm.)

- ACC 66CA-iQ - 600 x 600 (mm.)

- ACC 106CA-iQ - 1000 x 600 (mm.)

Grinding and dressing conditions are automatically calculated by using Okamoto's original iQ software.

Features :

- Semi-closed cover to provide safety and to prepare the grinding environment.

- Text-free interactive screen which can be set easily with the touch panel.

- Simple surface, groove, pitch, steps and side grinding cycles are achievable.

- Just be entering total and fine grinding allowance, and then, wheel grain size, the optimum grinding and dressing conditions are automatically calculated.

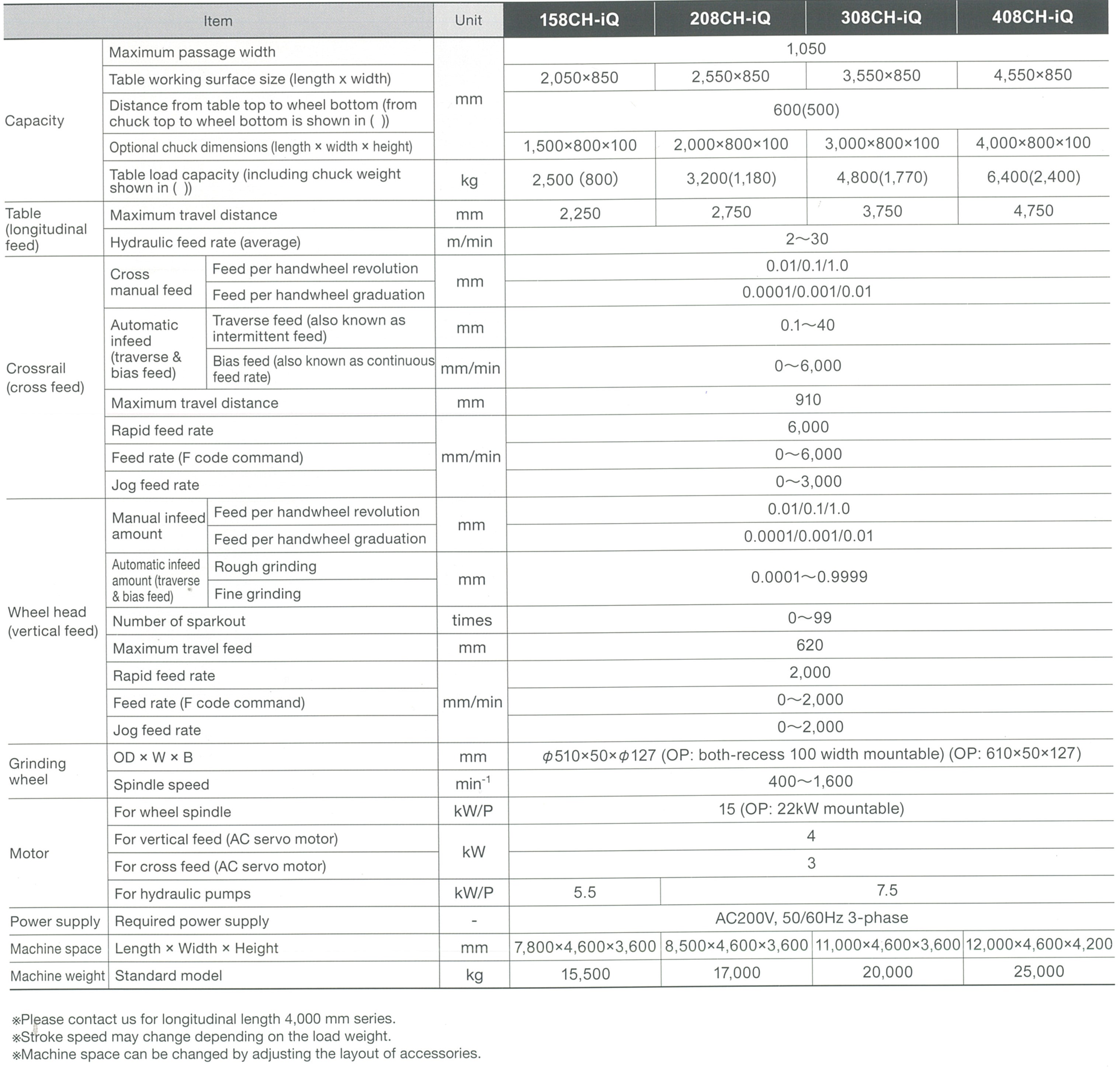

ACC-CH-iQ

Machine Lineup Standard chuck size (LxW)

- ACC 158CH-iQ - 1500 x 800 (mm.)

- ACC 208CH-iQ - 2000 x 800 (mm.)

- ACC 308CH-iQ - 3000 x 800 (mm.)

- ACC 408CH-iQ - 4000 x 800 (mm.)

Industry-leading double column grinding machine series towards a new era of high efficiency and automation for large grinding machines.

Features :

- Large size grinding machines could achieve high rigidity and precision with the double column structure.

- Globalization of production is realized with the text-free interactive iQ software.

- It supports the beginner operators with the functions to automatically calculating the grinding & dressing conditions.

- The factory is kept clean by adopting the slide cover over the open-top cover.

- Text-free user-friendly interactive iQ software is installed. The operation is simple for the data input completes by touching only 2 pages.

- The machine footprint is the same level with the conventional column series. With the high rigidity of the double column type, it contributes the improved productivity.

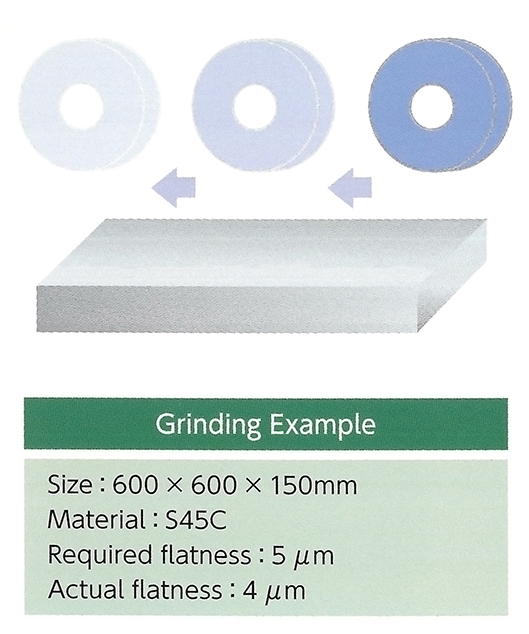

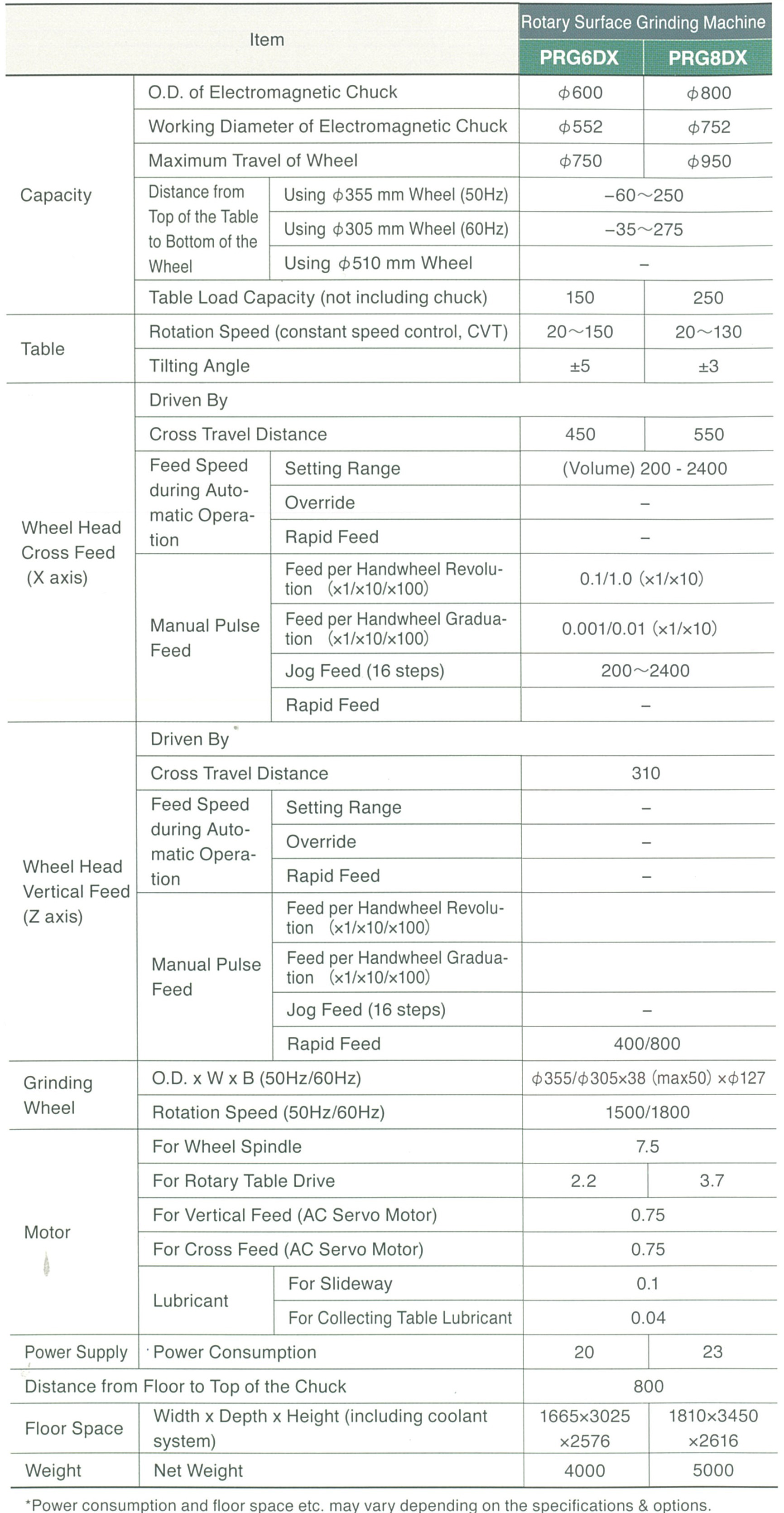

PRG-DX

Machine Lineup

- PRG 6DX

- PRG 8DX

Rotary Surface Grinding Machines have more than twice the productivity compared to reciprocating surface grinding machines. Achieving better stability & higher accuracy due to the highly rigid construction, we can control infeeds as low as 0.1 µm.

Features :

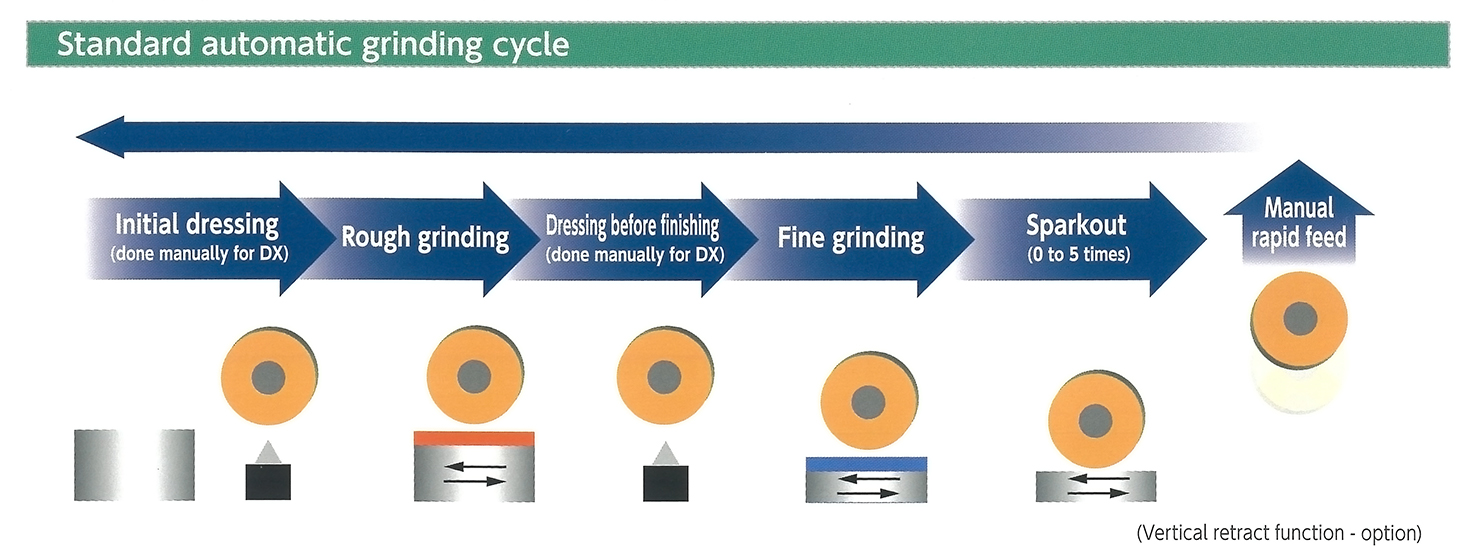

- Equipped with automatic cycle function of "coarse grinding -> fine grinding -> spark-out -> stop at workpiece peripheral end"

- The stoke limits of the outer and inner peripheral ends of the workpiece is set by jog feed teaching positions.

- Minimum vertical feed setting increment is 0.1 µm.

- Double-Column structure is used to maintains high rigidity and machine accuracy.

- Efficiency is established by the manual interruption function during the automatic cycle.

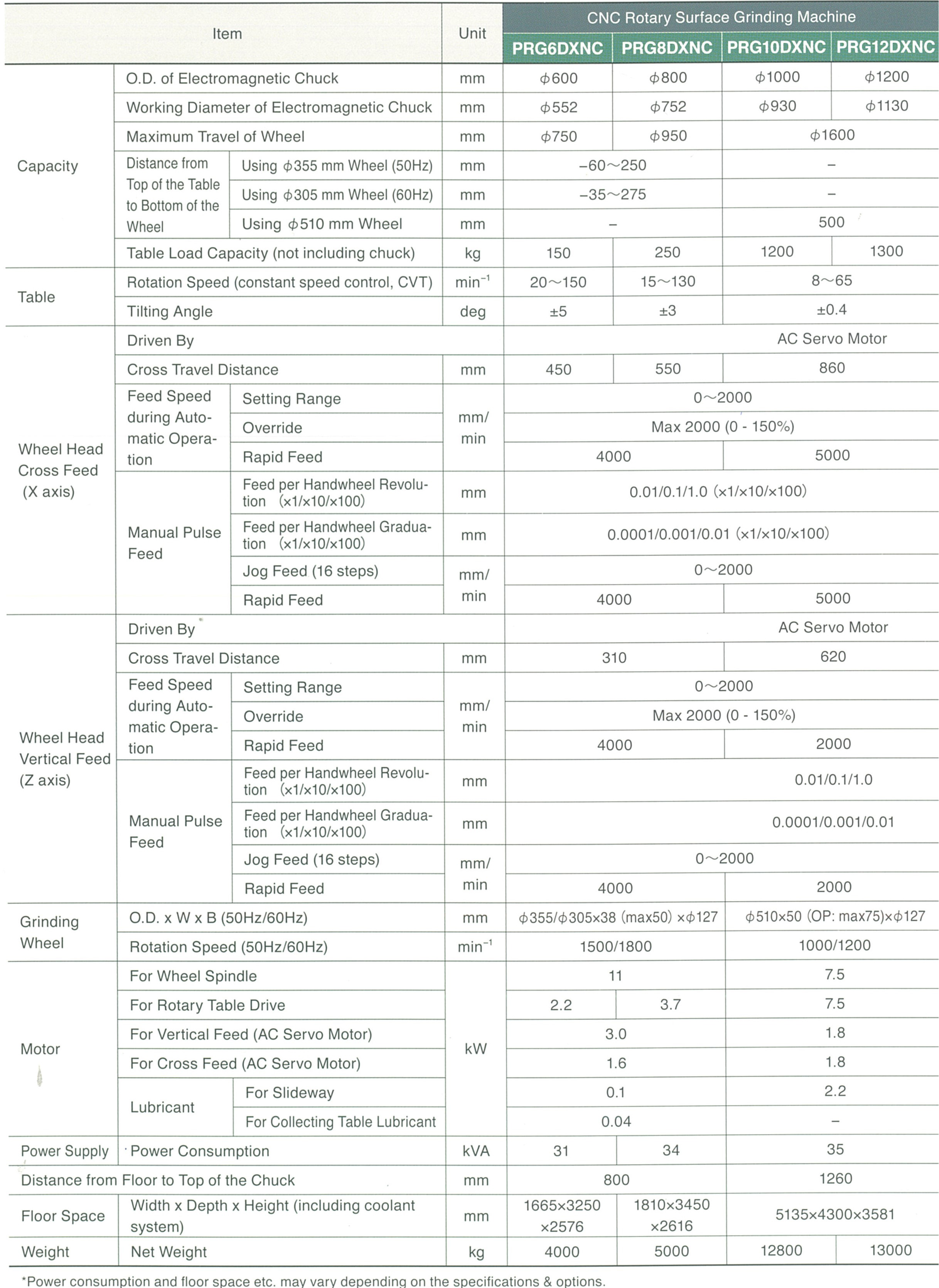

PRG-DXNC

Machine Lineup

- PRG 6DXNC

- PRG 8DXNC

- PRG 10DXNC

- PRG 12DXNC

CNC Precision Rotary Surface Grinding Machine Series Exert preeminent power in high-quality processing from the single item to mass-produced products

Features :

- Fully featured graphical interactive software supports automatic dressing during grinding cycle.

- Up to 4 steps can be ground using the graphic interactive software, between either traverse or plunge grinding cycles.

- Automation ready for high productivity in combination with measuring devices such as touch probe.

- Variable feed speed function controls the grinding amount, keeping it constant regardless of the position of the wheel over the rotary table.

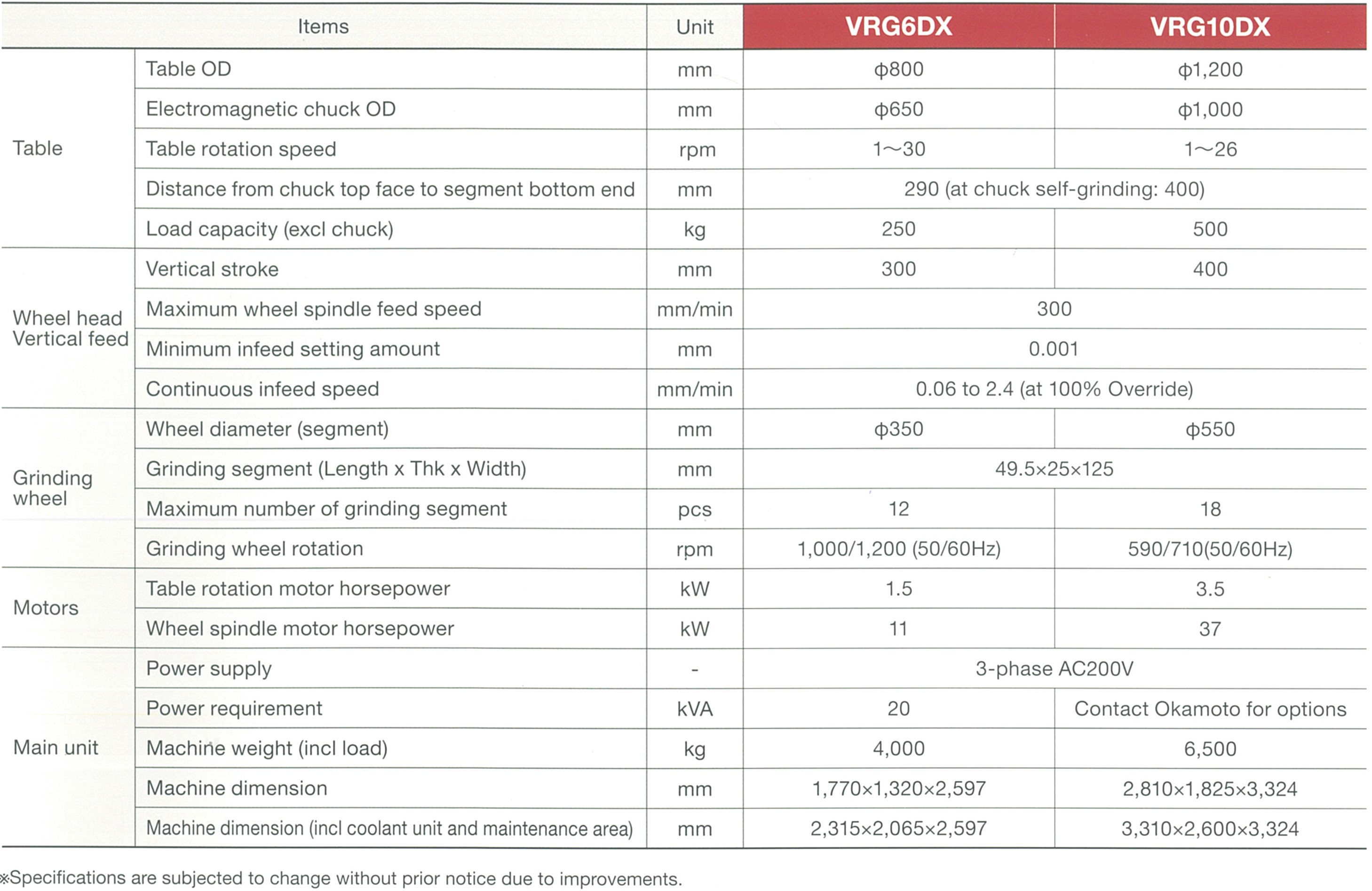

VRG-DX

Machine Lineup

- VRG 6DX

- VRG 10DX

User friendly, high rigidity, highly productive new vertical rotary grinding machine VRG-DX Series.

Features :

- High-efficiency and high-rigidity rotary grinding machine equipped with vertical wheel spindle.

- 3-point support column structure for easy adjustment. The combination of made-in-house highly rigid column and bed allows you to maintain high precision for a long operating time.

- Okamoto original FX controller can prevent operational mistake with minimum number of intuitive operations.

- Fully enclosed cover for safety and regulatory factory requirement.

- Ideal for grinding brittle materials such as glass/ceramics as well as metals.